Dr. Chamberlain giving a lecture to the students and faculty at the IIT student chapter’s first event.

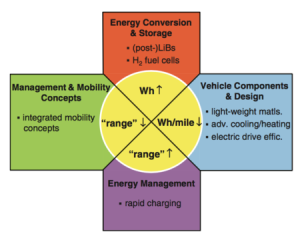

The Illinois Institute of Technology is one of ECS’s newest student chapters, and they held their first event on November 23, 2015. They received an excellent attendance rate of nearly one hundred students in addition to IIT faculty members and faculty from other near by institutions. This event included the director of the Argonne Collaborative Center for Energy Storage Science (ACCESS), Dr. Jeffrey Chamberlain, who is also the deputy director of the Joint Center for Energy Storage Research (JCESR). Dr. Chamberlain hosted a lecture that included information and a detailed analysis on the innovation of battery technologies.

Following the lecture, a Q&A session was held, which gave the students and faculty in attendance the opportunity to address questions produced from Dr. Chamberlain’s lecture. These questions included the topics of environmental issues, the life cycle of lithium ion batteries, development of lithium-air batteries and even government policy and funding. The formal lecture and Q&A session was followed with refreshments and continued discussion. The IIT student chapter is extremely grateful to Dr. Chamberlain for taking the time out of his very busy schedule to come and interact with the chapter at their first event.

Congratulations, IIT Student Chapter on a very successful kick-off event!