Global estimates report that nearly 600 million people are sickened by a foodborne illness annually, resulting in over 400,000 deaths. In the United States alone, foodborne illnesses such as Salmonella and E. coli result in an overall cost of $77 billion per year.

Researchers from the Washington State University (WSU) are looking to help put an end to the spread of foodborne illnesses with the development of a new and improved biosensor.

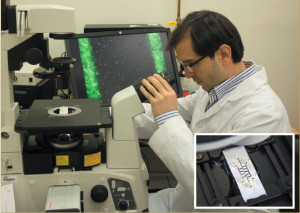

We’ve see in in the recent food recalls; harmful pathogens in food are almost always discovered after people have become sick. The work from WSU, led by ECS member Yuehe Lin, focuses on detecting and amplifying the signal of food pathogens, reducing the risk of small (but dangerous) pathogens to go undetected.