Call for Papers

The ECS Journal of Solid State Science and Technology is publishing a special collection of papers being presented at the International Conference on Advanced Materials and Mechanical Characterization (ICAMMC-2021). The meeting takes place December 2-4, 2021 in virtual format.

ICAMMC 2021 covers a wide range of emerging inter- and multi-disciplinary topics in developing advanced materials and their characterization at multiple length scales, manufacturing, and growth of innovative materials. It is an international forum for sharing knowledge and results in theory, computation, synthesis, fabrication, and characterization of advanced materials in structural, microstructural, small-scale mechanical aspects (not limited to), structure-property correlations, and technological applications. It is a common platform to present and discuss path-breaking research ideas and is expected to be an interface between academia and industry for societal needs. This focus issue centers on the advancements in design/fabrication, characterization and properties of next-generation materials for energy, electronic and dielectric applications. (more…)

A new process for growing wafer-scale 2D crystals could enable future super-thin electronics.

A new process for growing wafer-scale 2D crystals could enable future super-thin electronics. In a recently published ECS Journal of Solid State Science and Technology paper, ECS member Roger Loo and coauthors describe a new epitaxial growth technology and address the challenges of implementation. The open access article, “

In a recently published ECS Journal of Solid State Science and Technology paper, ECS member Roger Loo and coauthors describe a new epitaxial growth technology and address the challenges of implementation. The open access article, “ While tracking electrons moving through exotic materials, researchers have discovered intriguing properties not found in conventional, silicon-based semiconductors.

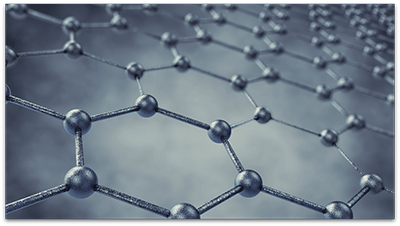

While tracking electrons moving through exotic materials, researchers have discovered intriguing properties not found in conventional, silicon-based semiconductors. New graphene printing technology can produce electronic circuits that are low-cost, flexible, highly conductive and water repellent, researchers report.

New graphene printing technology can produce electronic circuits that are low-cost, flexible, highly conductive and water repellent, researchers report. Incorporating organic electronic materials in the field of bioelectronics has indicated promising potential in interfacing with biological systems, including neuroscience applications. Researchers from Linköping University are taking a major step forward in that work with their development of the world’s first complementary electrochemical logic circuits that can function for long periods of time in water.

Incorporating organic electronic materials in the field of bioelectronics has indicated promising potential in interfacing with biological systems, including neuroscience applications. Researchers from Linköping University are taking a major step forward in that work with their development of the world’s first complementary electrochemical logic circuits that can function for long periods of time in water. Researchers have developed an inexpensive and scalable technique that can change plastic’s molecular structure to help it cast off heat.

Researchers have developed an inexpensive and scalable technique that can change plastic’s molecular structure to help it cast off heat.