ECS’s Shelley Minteer has developed a fuel cell that can convert jet fuel to electricity at room temperature without igniting the fuel.

Credit: Dan Hixson/University of Utah College of Engineering

The Electrochemical Society’s Shelley Minteer and her team of engineers at The University of Utah have developed the first room-temperature fuel cell that uses enzymes to help jet fuel produce electricity without need to ignite the fuel.

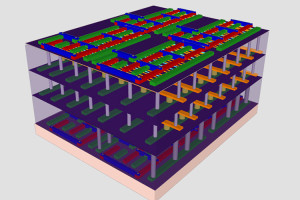

The new fuel cells will be able to be used to power portable electronics, off-grid power, and sensors.

The study was published in the American Chemical Society journal ACS Catalysis with Minteer as the senior author.

“The major advance in this research is the ability to use Jet Propellant-8 directly in a fuel cell without having to remove sulfur impurities or operate at very high temperature,” says Minteer. “This work shows that JP-8 and probably others can be used as fuels for low-temperature fuel cells with the right catalysts.”

The standard technique for converting jet fuel to electricity is both difficult, due to the sulfur content, and inefficient, with only 30 percent of the fuel converted to electricity under the best conditions.

This from The University of Utah:

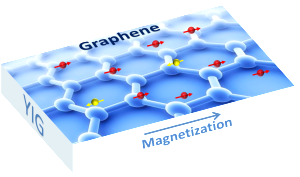

To overcome these constraints, the Utah researchers used JP-8 in an enzymatic fuel cell, which uses JP-8 for fuel and enzymes as catalysts. Enzymes are proteins that can act as catalysts by speeding up chemical reactions. These fuel cells can operate at room temperature and can tolerate sulfur.

Read the full article here.

Minteer is a valued member of ECS and is on the editorial board of the Journal of The Electrochemical Society and ECS Electrochemistry Letters – along with being a past chair of the Physical and Analytical Electrochemistry Division. You can also read her published research in our Digital Library.

Make sure to sign up for our e-Alerts so you don’t miss the newest, cutting-edge research!