The Electrochemical Society values professional and volunteer achievement in the multi-disciplinary sciences. The ECS awards reflect the professional recognition of peers. At meeting plenary sessions, participants from every symposia come together to recognize award winners—some of the greatest minds in the field—and learn about their latest research.

ECS Fellow David J. Lockwood received the Gordon E. Moore Award for Outstanding Achievement in Solid State Science and Technology at the plenary session of the 235th ECS Meeting. This award recognizes outstanding contributions to the fundamental understanding and technological applications of solid state materials, phenomena, and processes. Lockwood is a physicist and researcher emeritus at the National Research Council of Canada. His research centers on the optical properties of low-dimensional materials and focuses on Group IV and III-V semiconductor nanostructures. Lockwood presented “Silicon-Based Photonic Integrated Circuits: The Quest for Compatible Light Sources” at the 235th ECS Meeting Plenary Session. (more…)

For the past four decades, the electronics industry has been driven by what is called “

For the past four decades, the electronics industry has been driven by what is called “ Newly developed semiconductor materials are showing promising potential for the future of super-fast electronics.

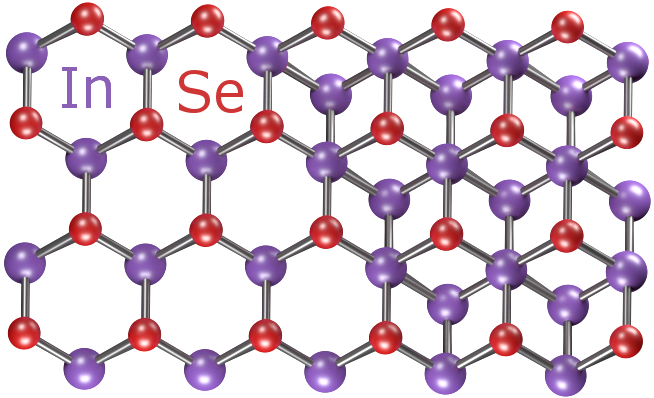

Newly developed semiconductor materials are showing promising potential for the future of super-fast electronics.