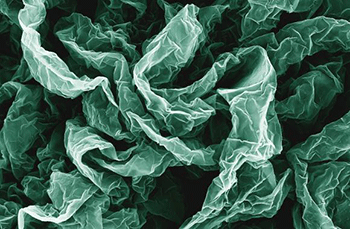

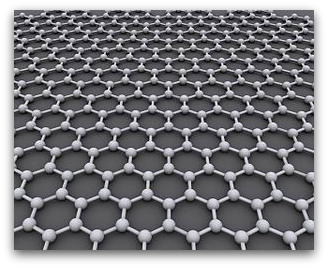

Researchers around the world have been talking about the potential of “wonder material” graphene since it first entered the field of materials science. However, for all its promising theoretical potential and applications, we’ve yet to see the material make its way to the market. Now, after an announcement by Chinese-based Guangzhous OED Technologies, graphene may make its first appearance in the marketplace within the next year.

The company just announced that they have developed what they are claiming is the “world’s first graphene electronic paper.” The e-paper, which is a display device that mimics the appearance of ordinary ink on paper, is expected to be taken to further heights with this development.

This from Phys:

The group at OED claims to have developed a graphene material that is suitable for use in making e-paper. Doing so, they also claim, allows for creating screens that are more bendable and that are also brighter because they will be able to display light with more intensity. They also suggest that because the end product will be carbon based, it should be cheaper to manufacture than current e-paper products which are based on metal indium.

A giant among giants

A giant among giants