When the temperature drops, we layer up. It’s the natural thing to do—until now. According to ScienceDaily, researchers at the University of Maryland have engineered a new fabric that can automatically change its properties to trap or release heat depending on external conditions.

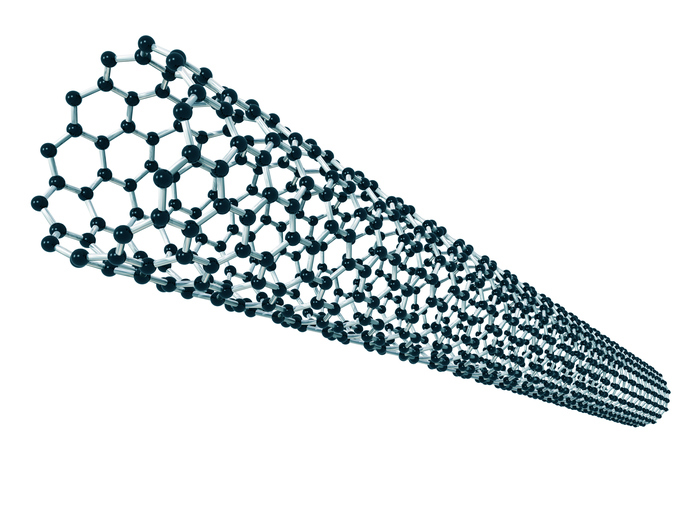

The textile, made from synthetic yarn with a carbon nanotube coating, is activated by temperature and humidity: making it the first of its kind. When conditions are warm and moist, such as those near a sweating body, the fabric allows heat to pass through. When conditions become cooler and drier, the fabric reduces the heat that escapes. Acting like blinds, the individual strands of yarn open and close to transmit or block heat.

Engineers are developing a new method of processing nanomaterials that could lead to faster and cheaper manufacturing of flexible, thin film devices, such as touch screens and window coatings.

Engineers are developing a new method of processing nanomaterials that could lead to faster and cheaper manufacturing of flexible, thin film devices, such as touch screens and window coatings. The introduction of purified carbon nanotubes appears to have a beneficial effect on the early growth of wheatgrass, according to scientists. But in the presence of contaminants, those same nanotubes could do great harm.

The introduction of purified carbon nanotubes appears to have a beneficial effect on the early growth of wheatgrass, according to scientists. But in the presence of contaminants, those same nanotubes could do great harm. A team of engineers has found a simple, economical way to make a nano-sized device that can lift many times its own weight.

A team of engineers has found a simple, economical way to make a nano-sized device that can lift many times its own weight. Sometimes the biggest advancements are the smallest in size.

Sometimes the biggest advancements are the smallest in size.