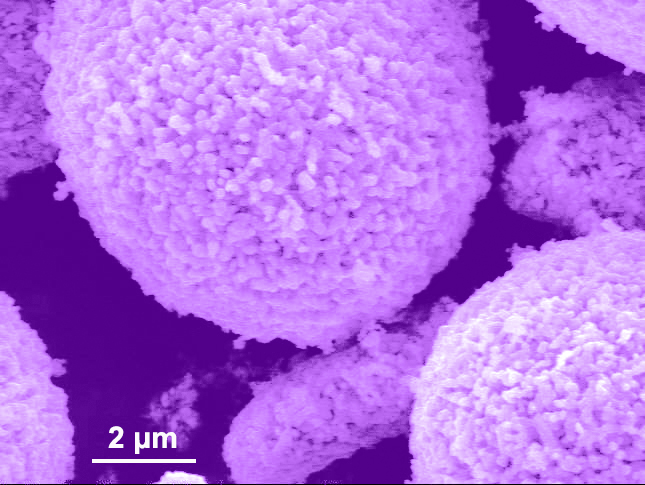

Cathode particles treated with the carbon dioxide-based mixture show oxygen vacancies on the surface.

Image: Laboratory for Energy Storage and Conversion, UC San Diego

An international team of researchers has recently demonstrated a 30 to 40 percent increase in the energy storage capabilities of cathode materials.

The team, led by ECS member and 2016 Charles W. Tobias Young Investigator Award winner, Shirley Meng, has successfully treated lithium-rich cathode particles with a carbon dioxide-based gas mixture. This process introduced oxygen vacancies on the surface of the material, allowing for a huge boost to the amount of energy stored per unit mass and proving that oxygen plays a significant role in battery performance.

This greater understanding and improvement in the science behind the battery materials could accelerate developments in battery performance, specifically in applications such as electric vehicles.

“We’ve uncovered a new mechanism at play in this class of lithium-rich cathode materials,” says Meng, past guest editor of JES Focus Issue on Intercalation Compounds for Rechargeable Batteries. “With this study, we want to open a new pathway to explore more battery materials in which we can control oxygen activity.”

This from University of California, San Diego:

Through characterization studies in collaboration with groups from Brookhaven National Laboratory and Oak Ridge National Laboratory, researchers provided several reasons why oxygen vacancies improved the cathode material’s performance. They explained that the vacancies allow lithium ions to move around more easily throughout the cathode, leading to high discharge capacity and faster discharge rates. The vacancies also increase the material’s stability by inhibiting the formation of highly reactive oxygen radicals at the cathode material’s surface, which are typically responsible for degrading the electrolyte while the battery is operating. This could mean longer battery lifetime, researchers said.

“But before we can decide if this is a promising step forward for batteries, we need to probe whether our technology can improve battery performance based on multiple metrics at once, not just whether it improves a single parameter,” Meng says. “We need to think of improving battery performance like we’re expanding on a spiderweb with multiple variables.”