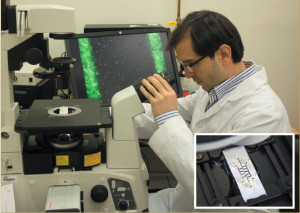

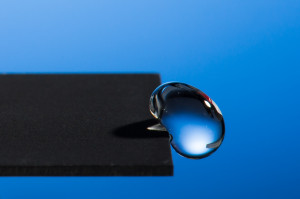

Professor Chunlei Guo has developed a technique that uses lasers to render materials hydrophobic, illustrated in this image of a water droplet bouncing off a treated sample.

Photo: J. Adam Fenster / University of Rochester

New super-hydrophobic metals developed at the University of Rochester could mean big things for solar innovation and sanitation initiatives.

The researchers, led by Professor Chunlei Guo, have developed a technique that uses lasers to render materials extremely water repellant, thus resulting in rust-free metals.

Professor Guo’s research in novel not in the sense that he and his team are creating water resistant materials, instead they are creating a new way to develop these super-hydrophobic materials by taking away reliance on chemical coatings and shifting to laser technology.