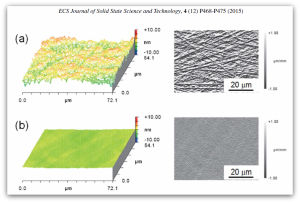

Microscopic interferometric images and slope images of SiC surface (a) before (PV: 23.040 nm, Ra: 1.473 nm, RMS: 1.885 nm) and (b) after (PV:

2.070 nm, Ra: 0.198 nm, RMS: 0.247 nm) polishing with soda-lime glass plate.

Guest post by Jennifer Bardwell, Technical Editor of the ECS Journal of Solid State Science and Technology (JSS).

This paper, from Kumamoto University in Japan, concerns a technique for abrasive-free polishing of silicon carbide (SiC). This topic is timely as SiC is an important material for wide bandgap electronics, both in its own right, and as a substrate for gallium nitride electronics. The reviewers note that:

“Defect free polishing of SiC surface has high significance” and that “The results are amazing”

In the words of the abstract: “The experimental results showed that an oxide layer was formed on the SiC surface as a result of the chemical reaction between the interfaces of the synthetic SiO2 glass plate and the SiC substrate. This generated oxide layer was effectively removed by polishing with the soda-lime SiO2 glass plate, resulting in an atomically smooth SiC surface with a root mean square roughness of less than 0.1 nm for 1.5 h. Obtained experimental results indicate that the component materials, temperature and water adsorptive property of the soda-lime SiO2 glass play an important role in the removal of the tribochemically generated layer on the SiC surface during this polishing.”