Have you ever wished you could increase your cellphone battery life? Well, that technology may very well already be here.

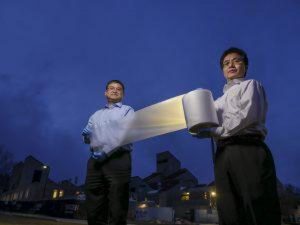

Researchers from AMBER, the Science Foundation Ireland Research Centre for Advanced Materials and BioEngineering, at Trinity College Dublin, have announced the development of a new material which offers the potential to improve battery life in everyday electronics, like smartphones, according to Irish Tech News.

The discovery could mean that the average phone battery life, roughly 10 hours of talk time, could increase to 30-40 hours.

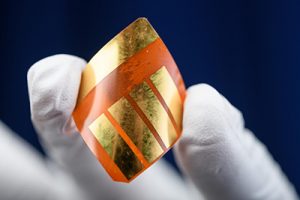

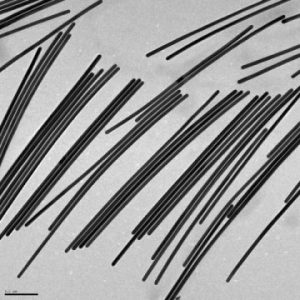

MXenes, an ink-based nanomaterial, not only significantly improves battery life, but it also offers its batteries the flexibility to become smaller in size, without losing performance. (more…)