Deadline for submitting abstracts

December 2, 2019

Submit today!

Topic Close-up #7

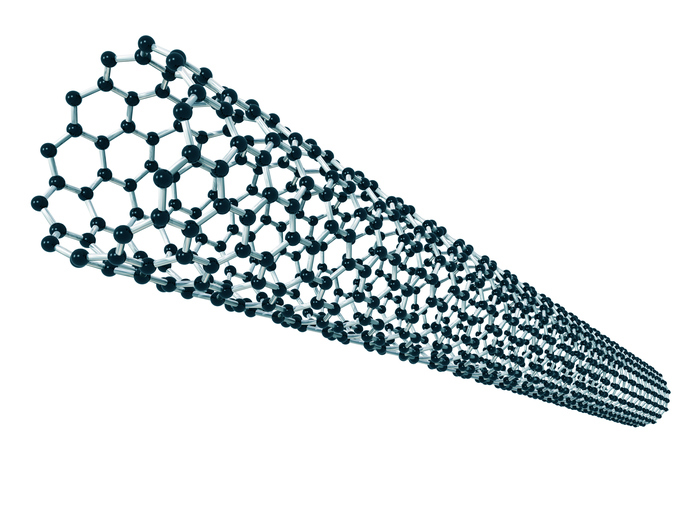

Symposium B02: Carbon Nanostructures in Medicine and Biology

Symposium focus:

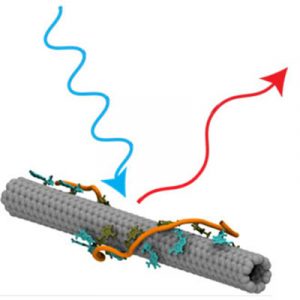

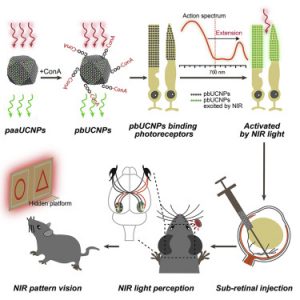

Nanocarbons have unique electronic, optical, and structural properties that enable new applications in biology and medicine. These may include but are not limited to assays, imaging tools, sensors, and therapeutics. The session covers areas including the development of new materials, characterization, uses/demonstration of pharmacology or effects in vitro and in vivo, plant biology applications, and clinical uses.

Nanocarbons Division SES Research Young Investigator Awardee and Keynote Speaker: Prof. Markita Landry, Assistant Professor, University of California at Berkeley

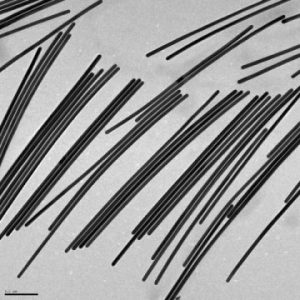

Engineers are developing a new method of processing nanomaterials that could lead to faster and cheaper manufacturing of flexible, thin film devices, such as touch screens and window coatings.

Engineers are developing a new method of processing nanomaterials that could lead to faster and cheaper manufacturing of flexible, thin film devices, such as touch screens and window coatings. The introduction of purified carbon nanotubes appears to have a beneficial effect on the early growth of wheatgrass, according to scientists. But in the presence of contaminants, those same nanotubes could do great harm.

The introduction of purified carbon nanotubes appears to have a beneficial effect on the early growth of wheatgrass, according to scientists. But in the presence of contaminants, those same nanotubes could do great harm.