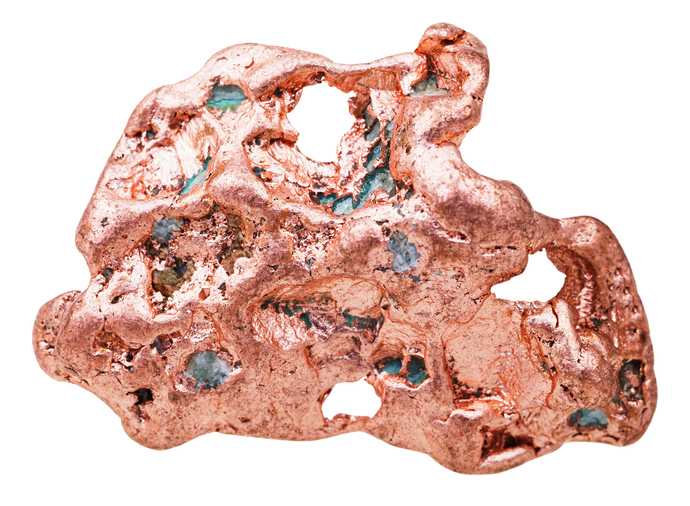

Researchers from MIT have developed a new way to extract copper by separating the commercially valuable metal from sulfide minerals in one step without harmful byproducts. The goal of this new process is to simplify metal production, thereby eliminating harmful byproducts and driving down costs.

Researchers from MIT have developed a new way to extract copper by separating the commercially valuable metal from sulfide minerals in one step without harmful byproducts. The goal of this new process is to simplify metal production, thereby eliminating harmful byproducts and driving down costs.

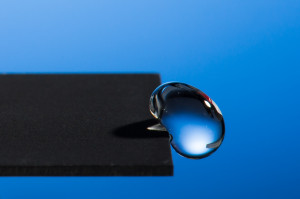

To achieve this result, the team used a process called molten electrolysis. Electrolysis is a common technique used to break apart compounds, often seen in water splitting to separate hydrogen from oxygen. The same process is also used in aluminum production and as a final step in copper production to remove any impurities. However, electrolysis in copper production is a multistep process that emits sulfur dioxide.

This from MIT:

Contrary to aluminum, however, there are no direct electrolytic decomposition processes for copper-containing sulfide minerals to produce liquid copper.