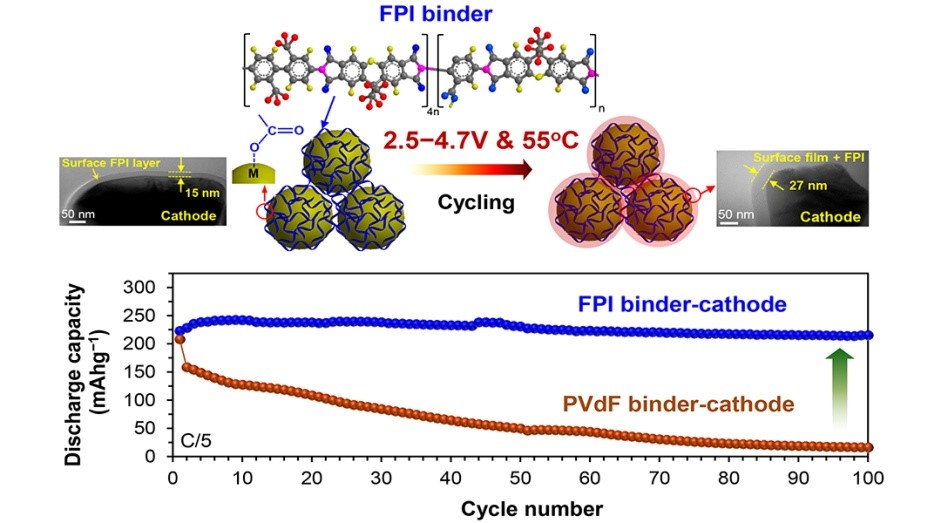

Superior high-voltage performance of Li-ion full cell with Li-rich layered oxide cathode prepared with fluorinated polyimide (FPI) binder, compared to the cell with conventional binder PVdF. (Click to enlarge.)

Image: Seung Wan Song

In order to increase the driving range of electric vehicles, researchers across the globe are working to develop lithium-ion batteries with higher energy storage. Now, scientists at Chungnam National University and Kumoh National Institute of Technology in Korea are taking a step toward that goal with their development of the first high-voltage cathode binder for higher energy Li-ion batteries.

Today’s Li-ion batteries are limited to charge to 4.2V due to the electrochemical instability of the liquid electrolyte and cathode-electrolyte interface, and loosening of conventional binder, polyvinylidenefluoride (PVdF), particularly at elevated temperatures. The fabrication of Li-rich layered oxide cathode with a novel high-voltage binder, as the research team demonstrated, can overcome these limitations.

Charging the batteries with Li-rich layered oxide cathode (xLi2MnO3∙(1−x)LiMO2, M = Mn, Ni, Co) to higher than 4.5V produces approximately doubled capacity than those with LiCoO2 cathode, so that doubled energy density batteries can be achieved.

Earlier works for charging the batteries to high voltages included the development of high-voltage electrolyte components or surface coating of cathode active material. Motivated by a different angle of approach, the scientists developed fluorinated polyimide (FPI) binder that plays vital multi-roles in strongly binding the particles of cathode active material though the chemical bonding of –COO-metal and in forming a robust surface protective films at those particles. It also enhances the electrochemical and thermal stabilities with −CF3 functionalities.

This unique binder chemistry significantly improves the structure of the cathode, cathode-electrolyte interfacial stability and its battery performance in the commercial liquid electrolyte in the absence of electrolyte additive, even under an aggressive operating condition of 4.7V and 55oC. A battery with the conventional binder, PVdF, fails under such aggressive battery operation condition. The research team believes that their multi-functional binder is good and convenient enough to apply to current cathode manufacturing process, and has a high impact on various high performance electrodes for commercial batteries.

The researchers are continuing to test the novel binder-integrated batteries and developing high-energy density battery technologies. A patent on the team’s invention is pending.

The findings were reported in the journal Advanced Functional Materials. (DOI: 10.1002/adfm.201704690)