The science behind climate change is alarming. Concentrations of greenhouse gases are rising at an alarming rate, land ice is dropping by 258 billion metric tons per year, and every passing year is proving to be the warmest year on record. Even with all of this information, it is difficult for some to grasp the complications climate change is causing due to the fact that an average person’s day-to-day life has remained relatively unharmed.

The science behind climate change is alarming. Concentrations of greenhouse gases are rising at an alarming rate, land ice is dropping by 258 billion metric tons per year, and every passing year is proving to be the warmest year on record. Even with all of this information, it is difficult for some to grasp the complications climate change is causing due to the fact that an average person’s day-to-day life has remained relatively unharmed.

“You can tell people that all these fossil fuels we’re using and all the CO2 that’s building up in the air is going to cause terrific problems. It’s only going to be when lower Manhattan is underwater that they’re going to start to respond,” said Allen J. Bard, the unofficial father of modern electrochemistry.

What Does Climate Change Look Like?

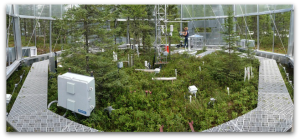

In order to make the reality of climate change more tangible, scientists with the Department of Energy are launching their SPRUCE (Spruce and Peatland Responses Under Climatic and Environmental Change) project to naturally demonstrate what the world could look like if there is no action taken on climate change.