Dr. Venkat Subramanian

Dr. Venkat Subramanian

Ernest Dashiell Cockrell II Professor of Engineering

Walker Department of Mechanical Engineering & Material Science Engineering

Affiliated Faculty, Oden Institute for Computational Engineering & Sciences

Texas Materials Institute

The University of Texas, Austin

Date: August 2, 2023

Time: 1300–1400h ET

Sponsor: BioLogic, TA Instruments – Waters, Hiden Analytical

Fast charging is researched heavily for the widespread implementation of lithium-ion batteries for electric vehicles. However, charging at high currents accelerates several parasitic reactions that lead to the degradation of the cell, affecting its lifetime. These reactions lead to loss of lithium inventory, loss of active material, and increased impedance in the cell. Examples of these side reactions include the growth of the solid-electrolyte interphase (SEI) layer, transition metal dissolution, and deposition, lithium plating, solvent oxidation, etc. These mechanisms degrade the cell and reduce its cycle life.

Physics-based multi-scale battery models solve for equations that govern the charge and mass balances within the cell. Using these detailed mathematical models, it is possible to study material degradation mechanisms and predict their impact on capacity loss under several operating conditions. These models can be used to design new batteries with appropriate materials and design parameters suited for any given purpose.

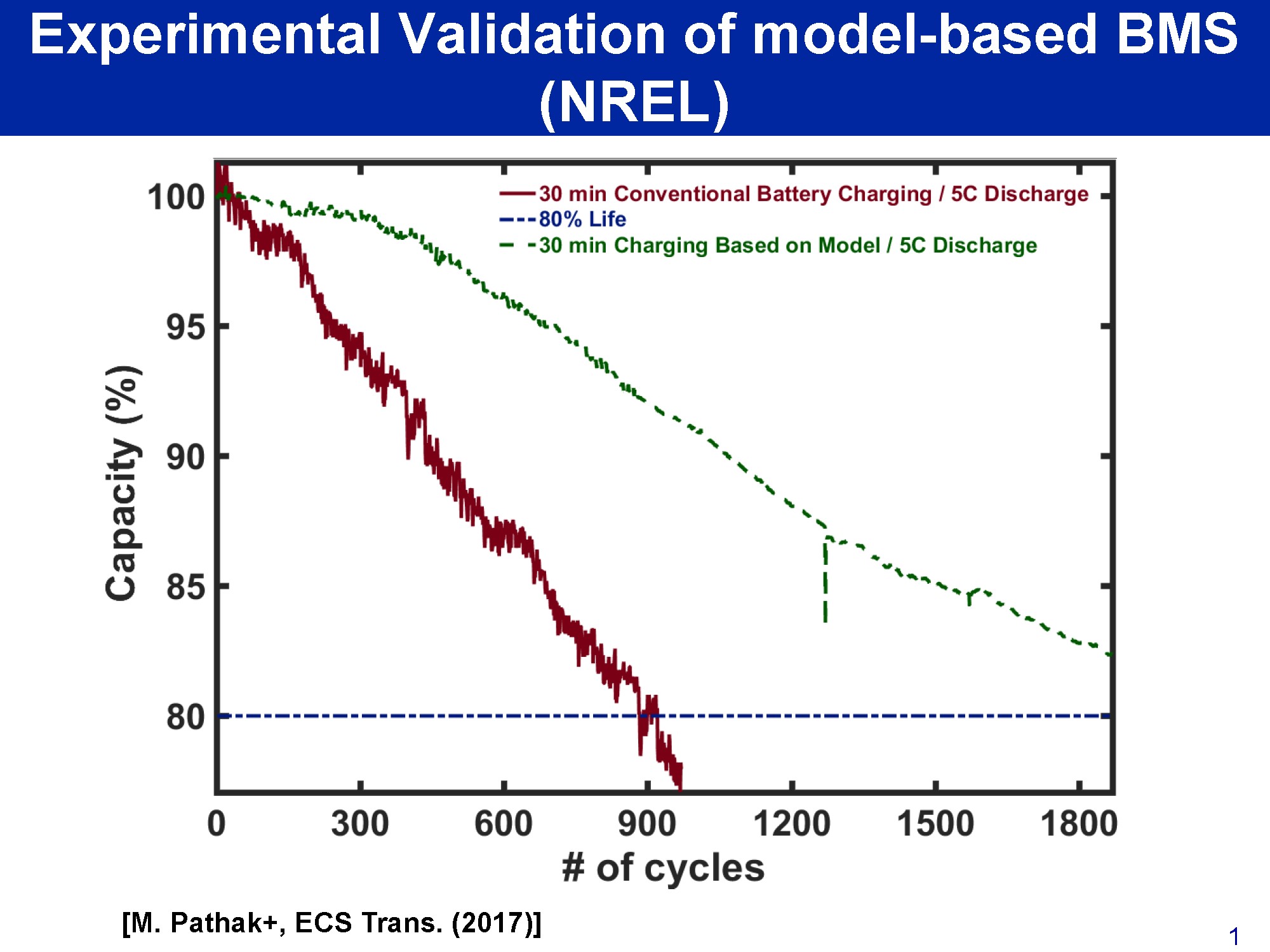

More critically, these models can be integrated with battery management systems (BMS) to control the cell’s performance. These models can further be used to design novel charging protocols that enable safe and optimal cell performance and suppress cell material degradation. The BMS monitors and maintains the voltage, current, and temperature, and estimates the internal states of the cell. Model-based BMS algorithms require fast codes that can predict and estimate battery parameters in real time and control the battery’s performance under different loads.

Currently, the BMS implements equivalent circuit models that inadequately predict the cell’s performance for various conditions and design parameters. This webinar presents the current efforts to move the models for BMS for current and next generation batteries.

An interactive Q&A session follows the presentation.

Benefits of attending the webinar

Learn about:

- How to charge your batteries faster in a safe manner;

- Understand the importance of models, algorithms, and software for BMS;

- Current trends in the field.

Venkat Subramanian

Dr. Venkat Subramanian is the Ernest Dashiell Cockrell II Professor of Engineering in the Department of Mechanical Engineering and Material Science Engineering, at the University of Texas at Austin (UT). Professor Subramanian is an elected Fellow of The Electrochemical Society, where he has served as an elected chair of the ECS Industrial Electrochemistry and Electrochemical Engineering (IE&EE) Division and elected technical editor. He is also a past elected chair of Area 1e: (Electrochemical Engineering) of the AIChE. His group aims to be the world’s leading group in model-based Battery Management Systems (BMS).

Learn more about upcoming ECS Webinars and review our previous webinar recordings.

We thank our webinar sponsors who make these complimentary programs possible.

Interested in presenting in the ECS Webinar Series? Email your presentation title and abstract to education@electrochem.org for consideration.