The Electrochemical Society hosted Dr. Reza Nazemi’s live webinar, “Designing materials and systems for decarbonizing chemicals and water industries,” on March 15, 2023. Dr. Nazemi took audience questions during a live Question and Answer session at the end of the presentation. He kindly answered, in writing, questions not answered during the broadcast. Find these responses below.

View Dr. Reza Nazemi’s Webinar

Q&A

What are the main challenges in scaling up electrochemical approaches for ammonia synthesis at an industrial scale?

There is a compromise between Faradaic efficiency and energy efficiency in direct electrochemical pathways for ammonia synthesis. While significant progress has been made to achieve high Faradaic efficiency, future studies should focus on improving energy efficiency of electrochemical technologies.

In addition, the separation and purification of ammonia in the liquid-phase electrolyte is another challenge that must be addressed. Ideally, it would be great to minimize or even mitigate these steps by operating our systems in gas-phase electrolysis systems.

Could you elaborate on methods to evaluate the long-term stability of catalyst materials and electrolyzers?

Advanced synchrotron spectroscopic techniques at United States Department of Energy (DOE) national labs (e.g., x-ray absorption spectroscopy) are leveraged to understand catalyst and electrolyzer stability under real operating conditions, providing invaluable insights into the stability of our proposed systems.

What is the role of transport in electrochemical reactions for ammonia synthesis?

We have designed rotating disk electrode experiments under the same operating conditions as we tested our batch electrolysis systems. At the working electrode rotating speed of 2500 rpm, we achieved comparable results as in batch systems at current densities up to 5 mA cm-2, suggesting transport has minimal impact on our electrocatalytic performance. We note that at significantly higher current densities (e.g., 1 A cm-2), the role of transport becomes dominant and using gas-phase systems (gas diffusion electrodes, membrane electrode assemblies) is highly recommended to minimize transport losses.

What is the limitation of operando Raman spectroscopy in the identification of intermediate species?

While operando Raman spectroscopy is a powerful technique to detect stable intermediate species such as hydrazine, it can hardly detect short-lived intermediate species during nitrogen reduction reactions.

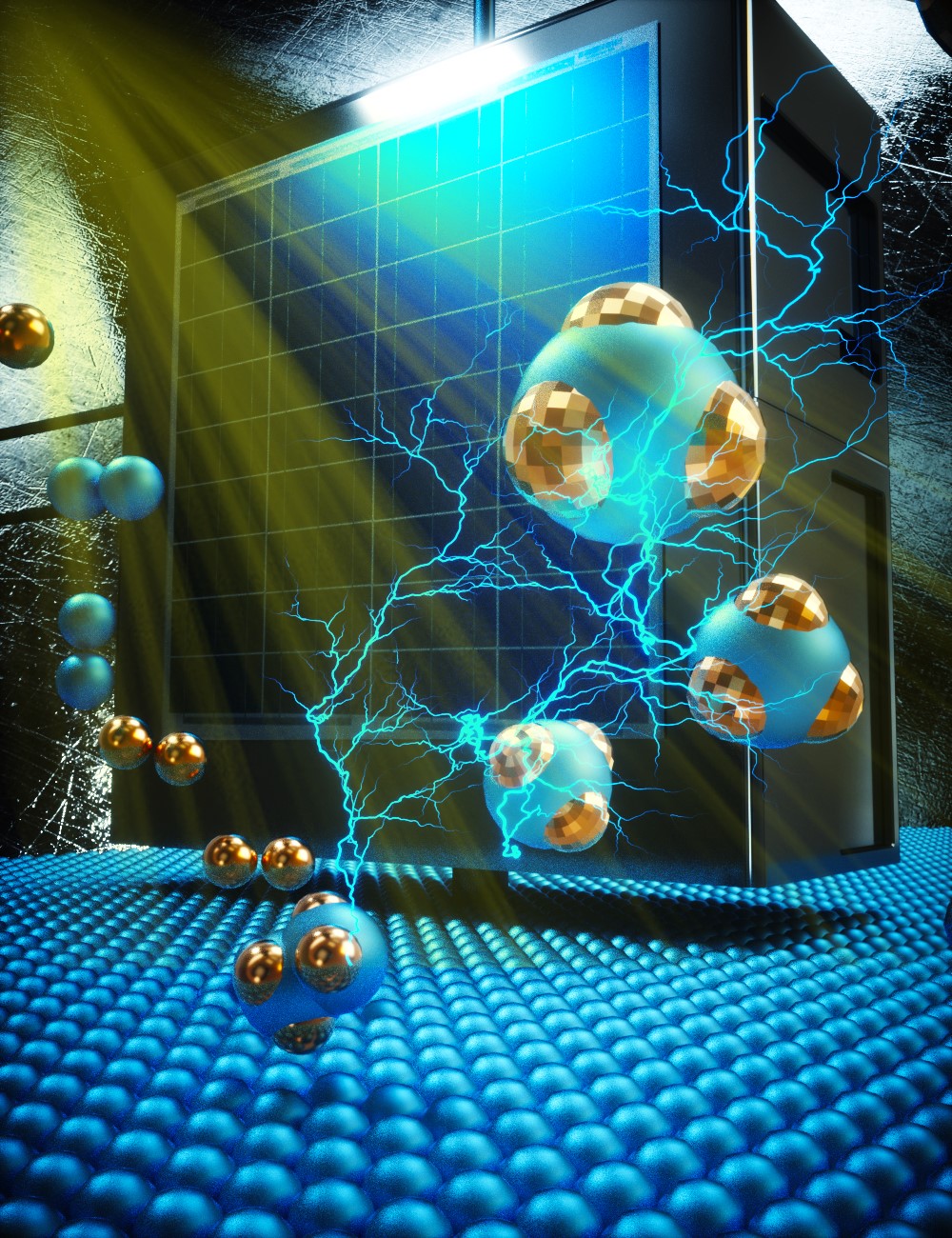

Could you explain the primary mechanism for the atomic distribution of palladium on the gold nanorod surface? Also, the same phenomena can be observed with constant wave laser.

A near-field ablation mechanism is a primary mechanism for the spallation of solid fragments (Pd nanoparticles) from the surface of Au plasmonic nanorods exposed to an intense femtosecond laser field. The nanoparticles’ plasmon field enhances the laser field at the hotspot on their surface, primarily at the tips of Au nanorods, inducing the reshaping or fragmentation of such spots.

How can chloride ions in wastewater impact the rate of electrochemical degradation?

The presence of chloride ions (Cl–) induces parasitic reactions that result in generating halogenated organic compounds, which are often more toxic and persistent than the original organic species. It is imperative to couple anodic oxidation with cathodic reduction reactions to ensure the continuous removal of organic species with little impact due to the presence of Cl– in the electrolyte.

How divalent cations (calcium and magnesium) can impact the rate of electrochemical nitrate reduction reaction?

Typically, divalent cations such as calcium and magnesium ions can result in scale formation on the electrode surface and block active sites for desired reactions, including the nitrate reduction reaction. Therefore, we should operate our electrochemical system in a sweet spot that is not thermodynamically favorable for the reduction of Ca2+ and Mg2+ and use various electrochemical approaches (e.g., polarity reversal or pulsed electrolysis) to minimize their impacts on the electrocatalytic performance.

NH3 is used especially for fertilizers. But nitrate can also be used for fertilizer. Several companies are looking at using electricity to make plasma that makes nitrate onsite for fertilizer, so no transport is needed. Is this also reasonable fertilizer?

Yes, it is an excellent idea to explore various electrified approaches (i.e., electrochemical or plasma-based systems) to generate nitrate from air and water.

As the amount of copper is more than the Pd, why is oxidation of Cu not taking place? How much 1Pd: 100 Cu electrode is stable? Have you checked the stability? How many hours is it running?

As Pd-Cu single atom alloyed was used as a catalyst for cathodic reduction (at negative applied potentials well below the thermodynamic potential of Cu, which is +0.34 V vs SHE), the Cu valency will not change while applying negative potentials (-0.4 to -1V vs SHE) for the nitrate reduction reaction.

What do you think about using screen-printed carbon electrodes in doing the in situ Raman for the determination of the catalytic site? Have you tried using screen-printed carbon electrodes for this purpose?

We initially used screen-printed carbon electrodes for in situ Raman, and we could confirm the generation and oxidation of ammonia at a high Raman shift. The challenge is the detection of intermediates due to the overlap with D and G features of carbon in the Raman spectrum. Maybe a screen-printed Au electrode is a better option.

Introducing electric current into a multicell electrolyzer is straightforward. However, how do you propose to introduce light energy into a photoelectrochemical electrolyzer in a stack configuration? Or are you limited to single cell designs such as you have shown?

Yes, stack testing by introducing light might be challenging. For large-scale applications, we can concentrate light to generate extremely high light intensity (1000 sun) and apply it to a single cell photoelectrochemical reactor for distributed and remote applications.

What membranes have you tried in your experiments?

We have primarily used cation exchange membranes (i.e., Nafions) that allow the transport of protons and block anions. We have washed Nafions membranes with dilute sulfuric acid and DI water before each use. We recently started to use Celgard membranes as well, to minimize potential contamination of the membrane by ammonia.

What optical transparent materials have you used in your photoelectrochemical reactors?

We used an acrylic sheet with 92 percent transparency on the cathode side.

Slide # 20: Why is the current density in the case of on-off measurement very low (nAcm-2)? Were those experiments done under bias?

The experiments were performed at the open circuit voltage (OCV). By applying bias, the photocurrent in the range of µA or mA could be achieved.

Plasmonic hot electrons have short lifetimes of the order of ns. But most of the electron transfer from the electrode surface to analyte occurs in ms scale (for example HER and OER). So how do we extract these hot electrons and use them in our electrocatalysis process?

Yes, that’s right. Here we aim to extend the lifetime of plasmonic nanomaterials, and we further combine them with semiconductors to achieve a prolonged lifetime of charge carriers in the order of µS to mS time scale that is suitable for catalysis.

What is the physics behind photocurrent generation in this plasmonic metal nanostructure? (Slide 27). How is it possible to create electron hole pairs inside the metal (conductor)? It seems impossible inside the metal.

Plasmonic nanomaterials have a unique feature in that they can behave similarly to semiconductors, generating hot electrons and holes if they are illuminated with an incident light with a wavelength that matches the frequency of oscillation of their free electrons. We can leverage those hot carriers in photocatalysis.

Are these truly nA or should it be mA on the Y axis of this plot?

The experiments were performed at the open circuit voltage (OCV). By applying bias, the photocurrent in the range of µA or mA could be achieved.

Have you worked with non-noble catalyst for N2 reduction? Or please let us know which metals or elements according to you can work for nitrogen reduction?

There are transition metal candidates for N2 reduction, including copper, nickel, and iron, worth exploring in new systems and chemistries.

What is the loading in SACs?

Our synthesized single-atom catalysts (SACs) are about 0.5-1 percent by weight. 20 mg of catalyst is mixed with 2 mL of isopropanol and 80 µL of Nafion binder (5 percent wt.) to make the ink. 0.5 mL of the ink is deposited on the 1×1 cm2 carbon paper electrode.

What is the hydrophobicity for CO SACs inks?

The CO SACs inks are hydrophilic as they are primarily in an isopropanol solution, but they are deposited on carbon paper that has 5 percent PTFE to enhance the hydrophobicity.

Does the cost of green ammonia need to be competitive with Haber-Bosch if the markets and incentives for the two are different? (Thinking about all the contracts for green ammonia in maritime applications)

Sure, maritime and heavy-duty transportations are exciting markets for green ammonia. By leveraging carbon tax and other governmental and environmental incentives, we do not need to be necessarily cost competitive to the Haber-Bosch process. But it is nice to see that we can even be cost-competitive to the Haber-Bosch process under some niche markets if we access very cheap renewable electricity, which might be very valuable for ammonia’s original use as a precursor for fertilizer in the Ag market.

How do you envision scaling these technologies to address the urgency of decarbonization?

At a large scale, we must be able to demonstrate electrochemical ammonia synthesis at energy efficiency (>60 percent) and industrially relevant current densities (a few A cm-2). In that case, this allows us to implement and adopt electrochemical ammonia synthesis for distributed applications.