Graphene could offer a new way to cool tiny chips in phones, computers, and other gadgets.

Graphene could offer a new way to cool tiny chips in phones, computers, and other gadgets.

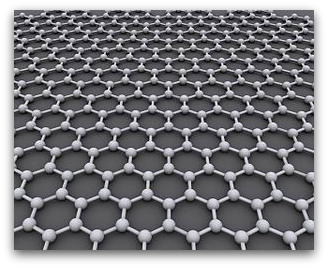

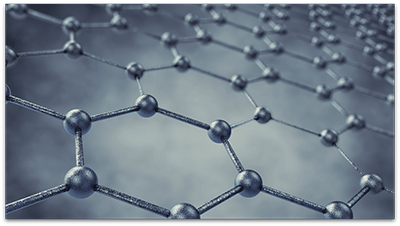

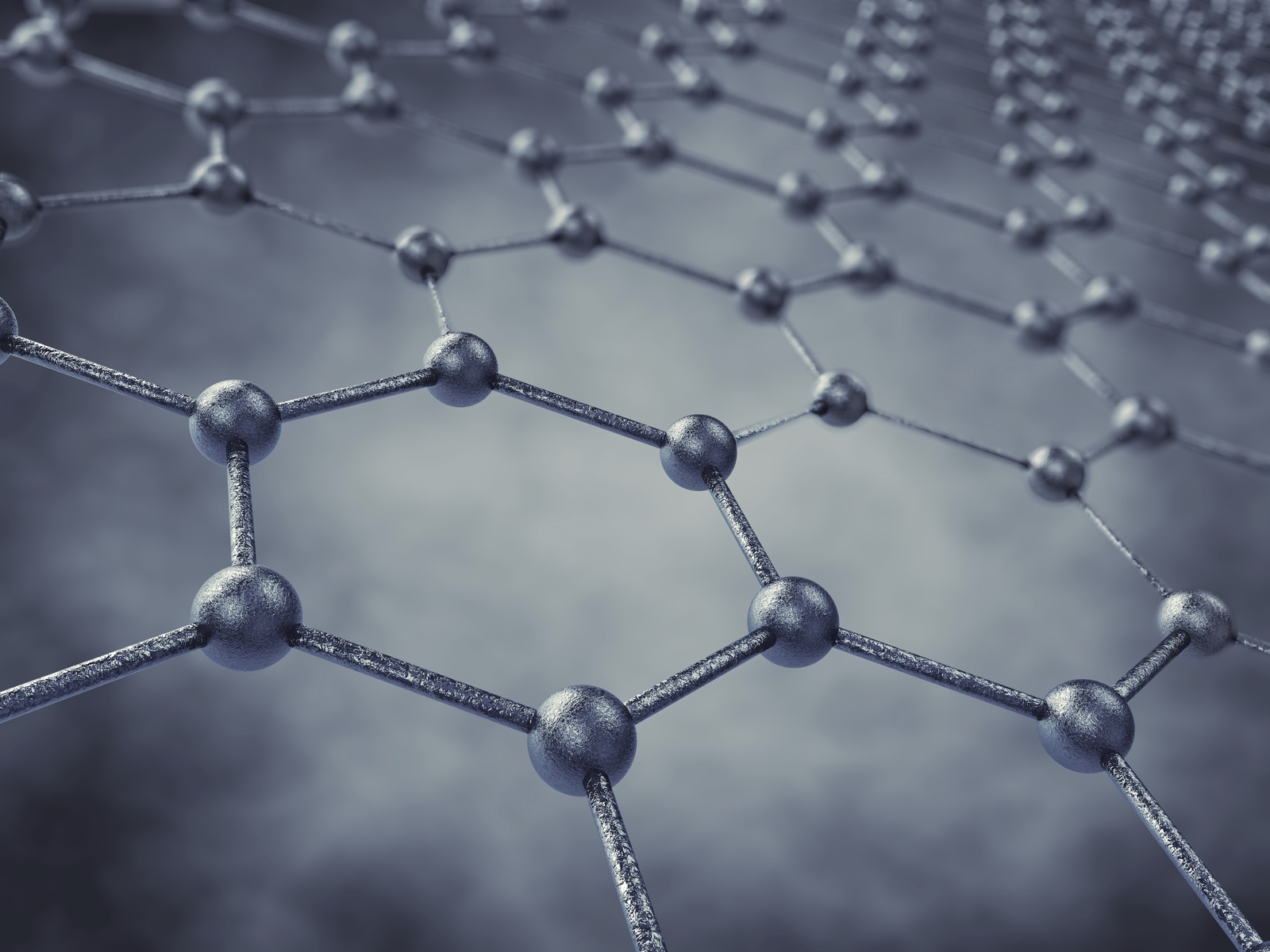

“You can fit graphene, a very thin, two-dimensional material that can be miniaturized, to cool a hot spot that creates heating problems in your chip,” says Eva Y. Andrei, a physics professor at Rutgers University. “This solution doesn’t have moving parts and it’s quite efficient for cooling.”

As electronics get smaller and more powerful, there’s an increasing need to for chip-cooling solutions. Researcher show in a paper published in the Proceedings of the National Academy of Sciences that using graphene combined with a boron nitride crystal substrate creates a very efficient cooling mechanism.

“We’ve achieved a power factor that is about two times higher than in previous thermoelectric coolers,” says Andrei.

The power factor refers to the effectiveness of active cooling. That’s when an electrical current carries heat away, as shown in this study, while passive cooling is when heat diffuses naturally.

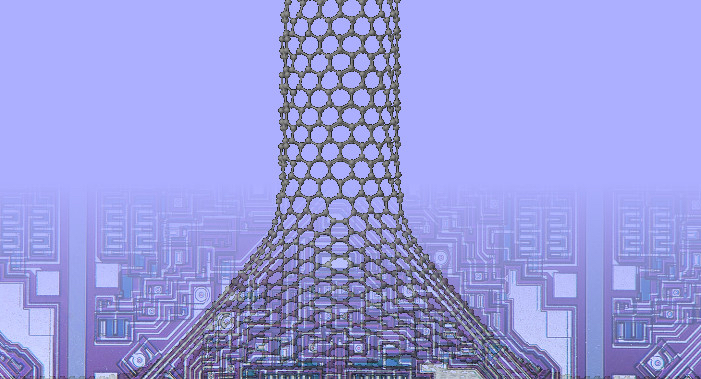

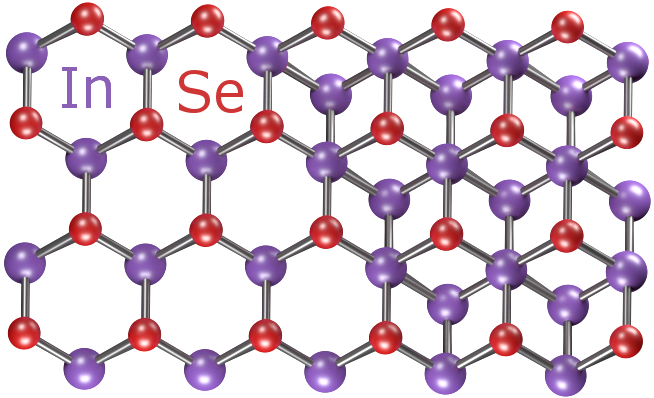

Newly developed semiconductor materials are showing promising potential for the future of super-fast electronics.

Newly developed semiconductor materials are showing promising potential for the future of super-fast electronics.