Hydro-Québec’s Center of Excellence in Transportation Electrification and Energy Storage is a world-class innovation hub in the field of battery materials for electric vehicles and other energy storage applications, both stationary and mobile.

Hydro-Québec’s Center of Excellence in Transportation Electrification and Energy Storage is a world-class innovation hub in the field of battery materials for electric vehicles and other energy storage applications, both stationary and mobile.

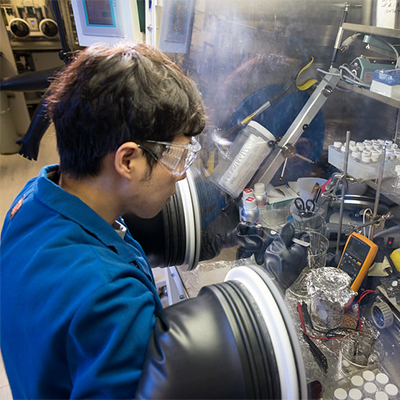

The Center’s efforts focus on advanced lithium-ion batteries and solid state batteries. Its know-how, impressive intellectual property portfolio, and leading-edge facilities draw interest from around the world and make it an essential partner for major industry players involved in the development of tomorrow’s battery materials and technologies.

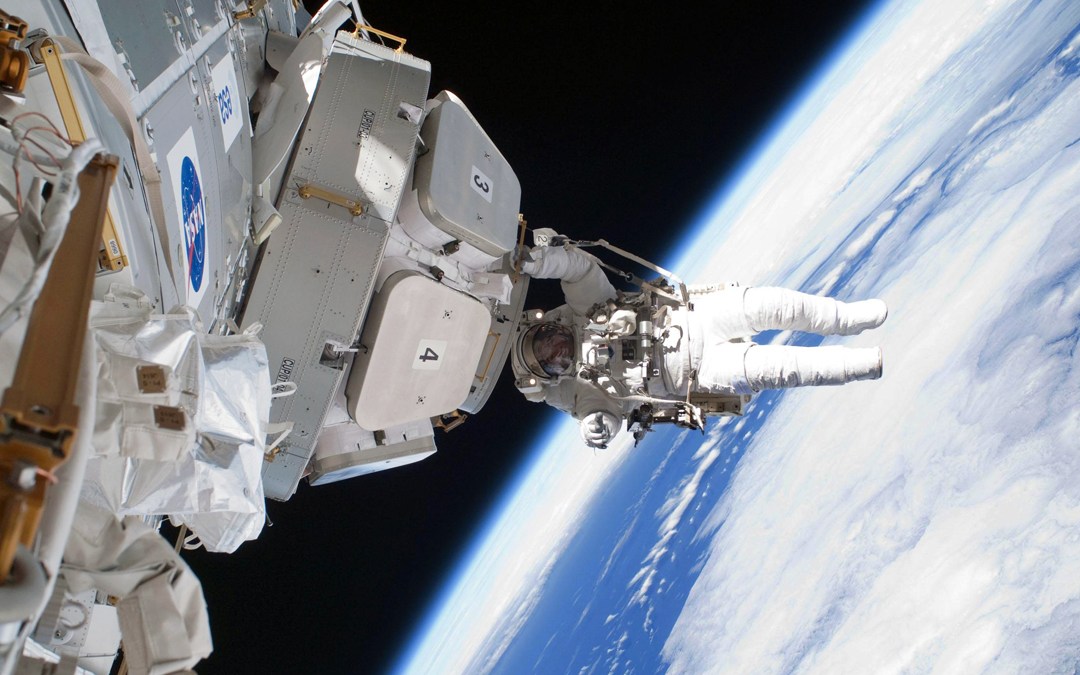

The Center of Excellence is reinventing energy for the electrified world of the future through its research on a number of fronts: battery materials, electrodes, electrochemical cells, modules, and battery packs. Our aim is to develop ultra-high-performance battery technologies and storage systems that will accelerate transportation electrification and make it possible to bring more renewables onto power grids, on a global scale. If we want to leave a viable planet to future generations, the time to act is now.