A recently published article in The Scientist tells a growingly familiar tale in scholarly publishing: predatory publishers taking advantage of, and often times profiting from, researchers across the globe.

The term “predatory publishers” was coined by University of Colorado Denver librarian, Jeffrey Beall, nearly a decade ago. These publishers disseminate plagiarized or poorly reviewed content, taking advantage of a pay-to-publish open access system by charging authors high prices to disseminate their content while all but eliminating the peer review process. In the case of the article published in The Scientist, these predatory journals even trick established researchers to agree to have their names listed on editorial boards, falsley presenting themselves as credible start-up journals. While this may bolster a journal’s credibility at first glance, it often doesn’t go beyond a name listed on a website, with little to no communication from the journal to the editors.

(RELATED: “For-science or For-profit?”)

And if predatory publishers can’t trick honest researchers, that publisher may just recruit a fake editor. A recent investigation, spearheaded by Nature, found that dozens of academic journals have been recruiting fake editors and offering them a place on their editorial board.

According to reports from the Hanken School of Economics, predatory journals increased their publication volume from 53,000 to 420,000 articles per year between 2010 and 2014. Taking article processing charges into account, the report estimates that all-in-all, the predatory publishing market was worth at $74 million in 2014.

(more…)

ECS Transactions 77(11) “Selected Proceedings from the 231st ECS Meeting: New Orleans, LA – Spring 2017,” has just been published.

ECS Transactions 77(11) “Selected Proceedings from the 231st ECS Meeting: New Orleans, LA – Spring 2017,” has just been published.

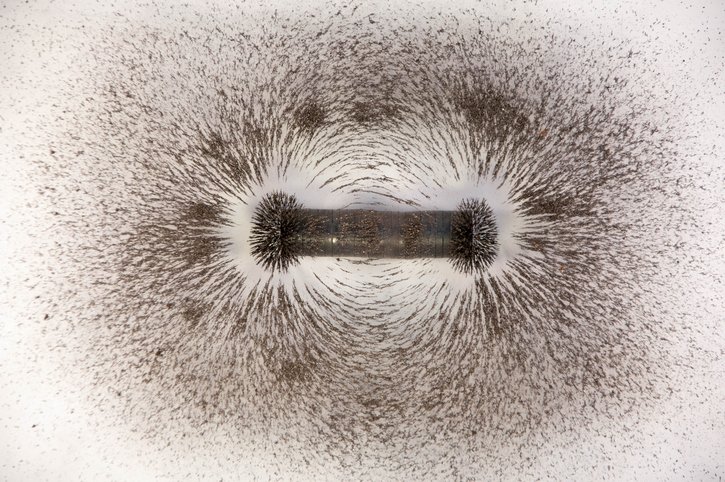

Researchers have found a way to use magnetic nanoparticle clusters to punch through biofilms to reach bacteria that can foul water treatment systems.

Researchers have found a way to use magnetic nanoparticle clusters to punch through biofilms to reach bacteria that can foul water treatment systems.

Researchers from Lappeenranta University of Technology (LUT) and VTT Technical Research Centre of Finland have successfully created food out of electricity and carbon dioxide, which they hope could one day be used to help solve world hunger.

Researchers from Lappeenranta University of Technology (LUT) and VTT Technical Research Centre of Finland have successfully created food out of electricity and carbon dioxide, which they hope could one day be used to help solve world hunger. A new device improves on the sensitivity and versatility of sensors that detect doping in athletics, bomb-making chemicals, or traces of drugs. It could also cut costs.

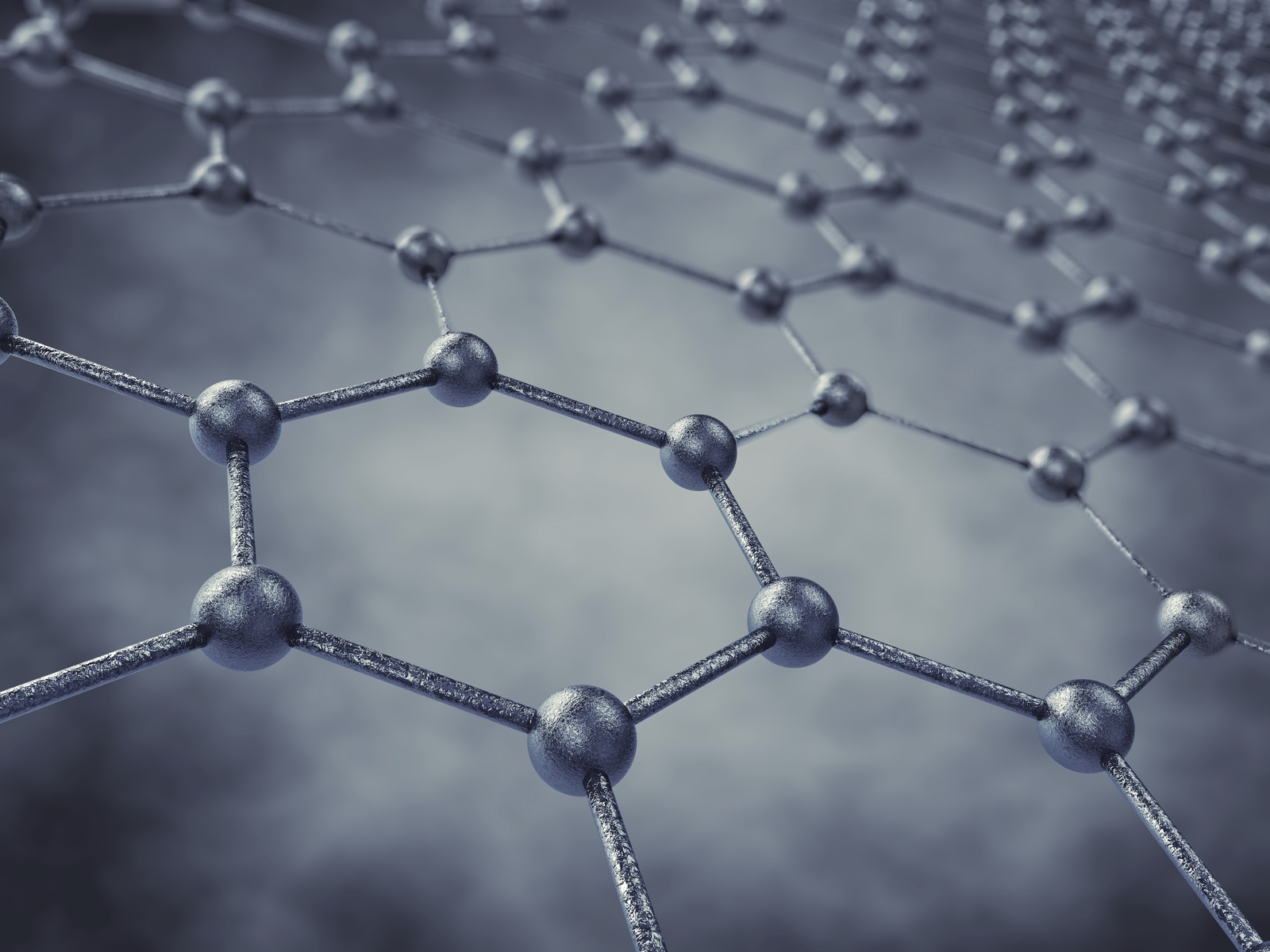

A new device improves on the sensitivity and versatility of sensors that detect doping in athletics, bomb-making chemicals, or traces of drugs. It could also cut costs. Scientists have turned wood into an electrical conductor by making its surface graphene.

Scientists have turned wood into an electrical conductor by making its surface graphene.

When will cars powered by gas-guzzling internal combustion engines become obsolete? Not as soon as it seems, even with the latest automotive news out of Europe.

When will cars powered by gas-guzzling internal combustion engines become obsolete? Not as soon as it seems, even with the latest automotive news out of Europe.