Battery fires led to the recall of nearly 2 million Samsung Galaxy Note 7 smartphones. In order to address this safety concern, researchers at Stanford University have identified 21 solid electrolytes for solid state batteries that could power the next-generation of electronics.

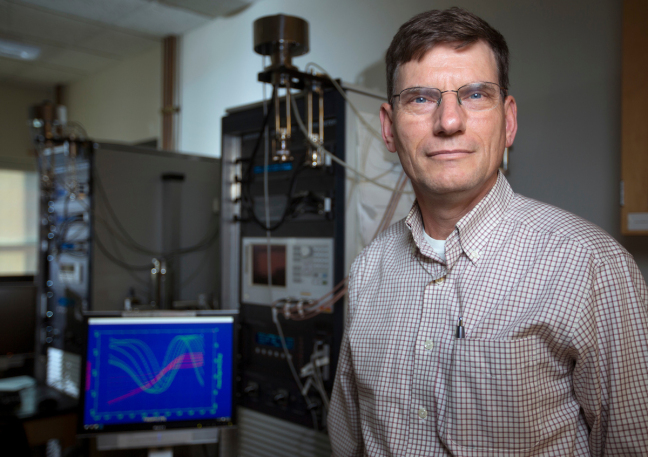

“Electrolytes shuttle lithium ions back and forth between the battery’s positive and negative electrodes,” says lead author of the study Austin Sendek, a doctoral candidate at Stanford University, who worked with ECS member Yi Cui on this research. “Liquid electrolytes are cheap and conduct ions really well, but they can catch fire if the battery overheats or is short-circuited by puncturing.”

“The main advantage of solid electrolytes is stability,” Sendek says. “Solids are far less likely to blow up or vaporize than organic solvents. They’re also much more rigid and would make the battery structurally stronger.”

Lithium-ion batteries supply billions of portable devices with energy. While current Li-ion battery designs may be sufficient for applications such as smartphones and tablets, the rise of electric vehicles and power storage systems demands new battery technology with new electrode materials and electrolytes.

Lithium-ion batteries supply billions of portable devices with energy. While current Li-ion battery designs may be sufficient for applications such as smartphones and tablets, the rise of electric vehicles and power storage systems demands new battery technology with new electrode materials and electrolytes. Recent safety concerns with lithium-ion batteries exploding in devices such as the Samsung Galaxy Note 7 phone and

Recent safety concerns with lithium-ion batteries exploding in devices such as the Samsung Galaxy Note 7 phone and  Just over ten years ago, the number of electric vehicles on the road could be counted in the hundreds. Now, more than

Just over ten years ago, the number of electric vehicles on the road could be counted in the hundreds. Now, more than