In an effort to increase security on airplanes, the U.S. government is considering expanding a ban on lithium-ion based devices from cabins of commercial flights, opting instead for passengers to transport laptops and other electronic devices in their checked luggage in the cargo department. However, statistics from the Federal Aviation Administration suggest that storing those devices in the cargo area could increase the risk of fires.

In an effort to increase security on airplanes, the U.S. government is considering expanding a ban on lithium-ion based devices from cabins of commercial flights, opting instead for passengers to transport laptops and other electronic devices in their checked luggage in the cargo department. However, statistics from the Federal Aviation Administration suggest that storing those devices in the cargo area could increase the risk of fires.

The FAA reports that batteries were responsible for nine airline fires in 2014. The number grew to 16 in 2015 and further to 31 in 2016. Most fires were able to be extinguished by passengers.

According to Homeland Security Secretary John Kelly, the U.S. government is considering expanding the ban to 71 additional airports.

(READ: “What’s Next for Batteries?” with Robert Kostecki.)

Mainstream concern regarding lithium-ion battery safety became widespread in 2016 when videos of hoverboards exploding began to emerge. Since then, news reports of smartphone and laptop batteries have emerged.

Assuming that the deployment of carbon removal technology will outpace emissions and conquer global climate change is a poor substitute for taking action now, say researchers.

Assuming that the deployment of carbon removal technology will outpace emissions and conquer global climate change is a poor substitute for taking action now, say researchers. In its first “

In its first “ In 2016,

In 2016,  The U.S. Department of Energy spends

The U.S. Department of Energy spends  The

The  U.S. Secretary of Energy Rick Perry in April

U.S. Secretary of Energy Rick Perry in April  The consumer demand for seamless, integrated technology is on the rise, and with it grows the Internet of Things, which is expected to grow to a

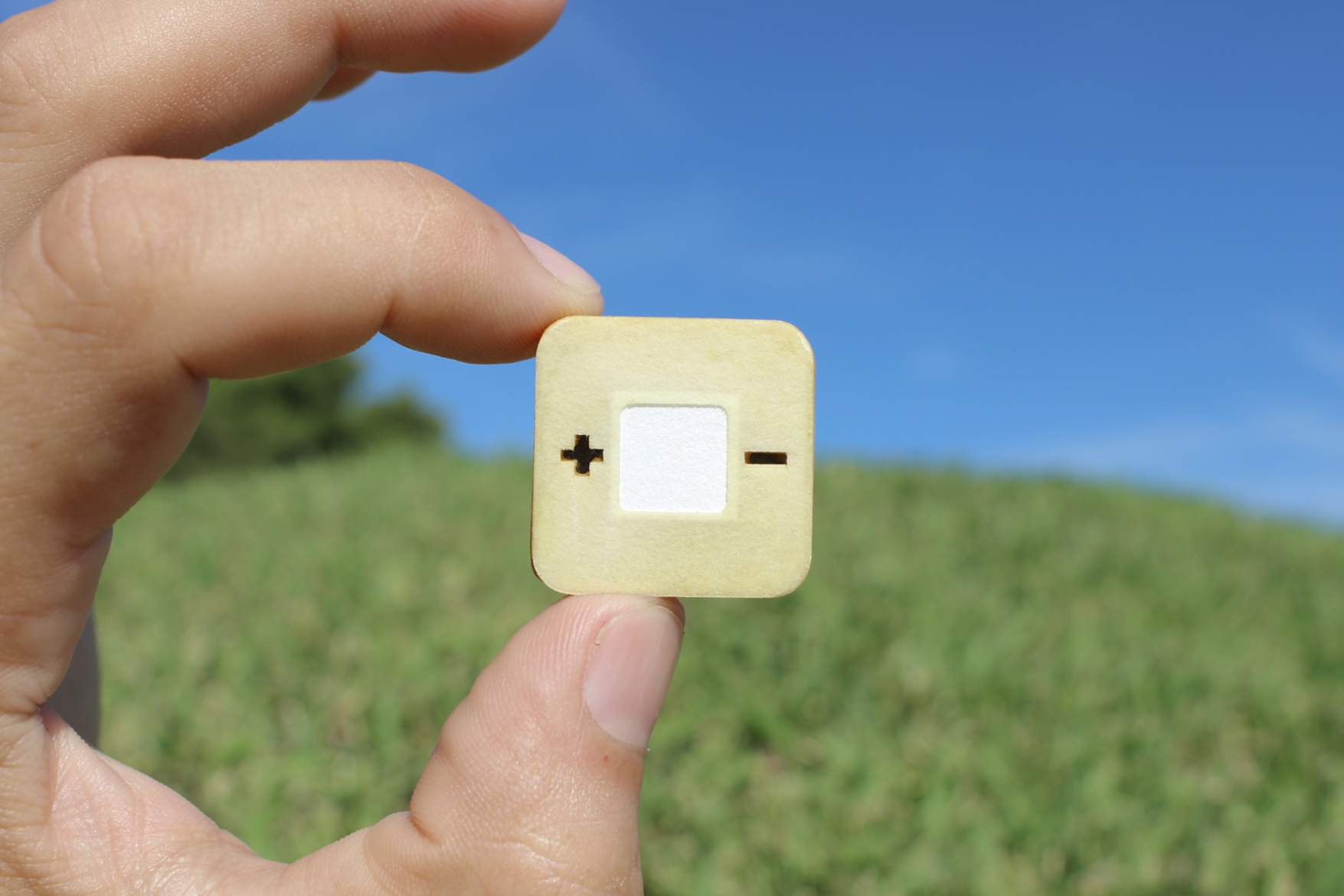

The consumer demand for seamless, integrated technology is on the rise, and with it grows the Internet of Things, which is expected to grow to a  Lithium-ion batteries power a vast majority of the world’s portable electronics, but the magnification of recent safety incidents have some looking for new ways to keep battery-related hazards at bay. The U.S. Navy is one of those groups, with chemists in the U.S. Naval Research Laboratory (NRL) unveiling a new battery, which they say is both safe and rechargeable for applications such as electric vehicles and ships.

Lithium-ion batteries power a vast majority of the world’s portable electronics, but the magnification of recent safety incidents have some looking for new ways to keep battery-related hazards at bay. The U.S. Navy is one of those groups, with chemists in the U.S. Naval Research Laboratory (NRL) unveiling a new battery, which they say is both safe and rechargeable for applications such as electric vehicles and ships.